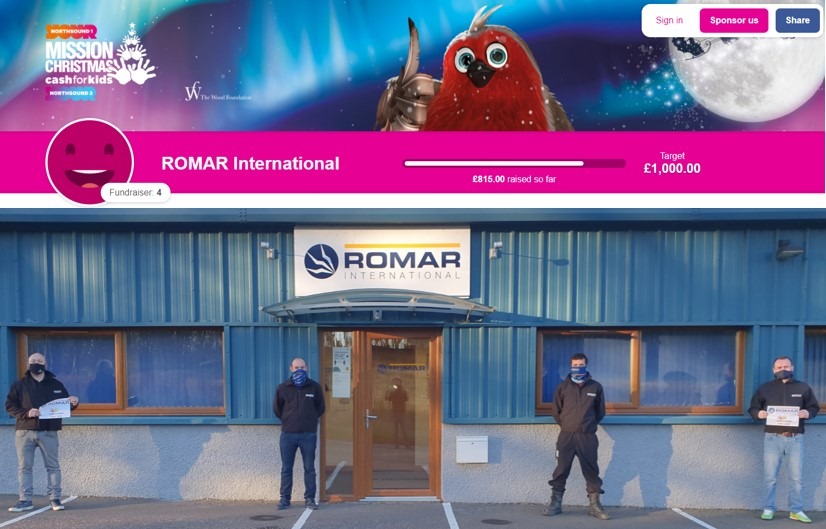

With the current COVID crisis and its effect on many people’s livelihoods, the ROMAR team have decided to cancel our usual Secret Santa and put our effort into fundraising for those less fortunate than ourselves. To raise funds for the Mission Christmas Cash for Kids appeal, on the 4th