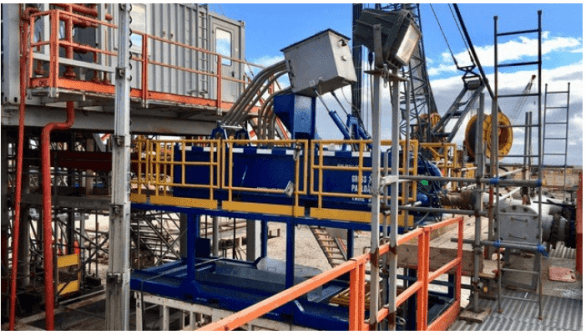

The ROMAR workshop team have been working hard to prepare for a series of four new SS1000 swarf handling projects. These systems are all destined for operations in offshore Europe and are all expected to load out within the week. If we can help optimise milling performance on your