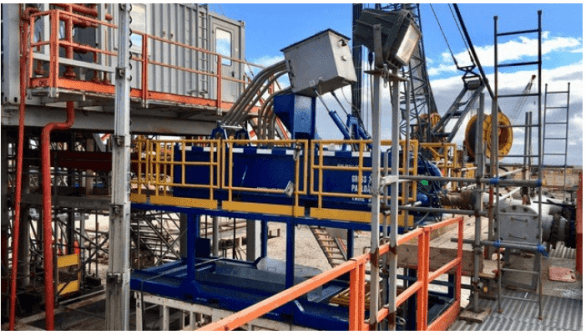

We’ve just air freighted another SS1000 swarf system to the Middle East for a major operator’s upcoming well abandonment campaign. The system was loaded into a Cargolux 747 freighter at Prestwick for shipment to the Gulf. Thanks to the hard work of the ROMAR operations and workshop teams as