The ROMAR team have completed the latest well on an ongoing UK milling campaign. The client has reported that our SS1000 system is “working extremely well” with 2,998 ft of casing and liner milled at an average ROP of 5 ft/hr with zero non-productive time or lost time incidents on the job.

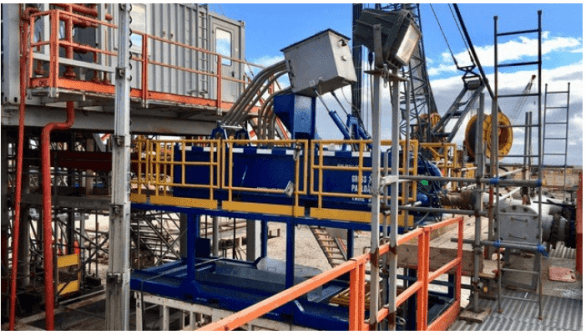

Designed with efficient metal particle separation and manual handling safety at its core, the ROMAR® Swarf Handling System provides a safe, highly efficient solution for the processing of liquids or slurries contaminated with metallic particles.

Capable of operating at flow rates of up to 1,500gpm while recovering debris at up to 2,000 Kg/hr, the The ROMAR® Swarf Handling System allows the full optimisation of milling parameters. Thus saving our clients rig days and considerable expense.

For more information on ROMAR SS1000 Swarf Management System, please visit Products