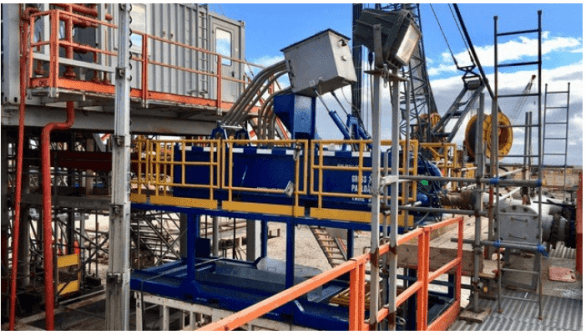

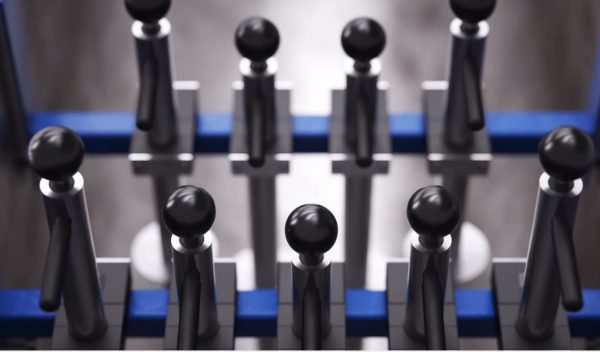

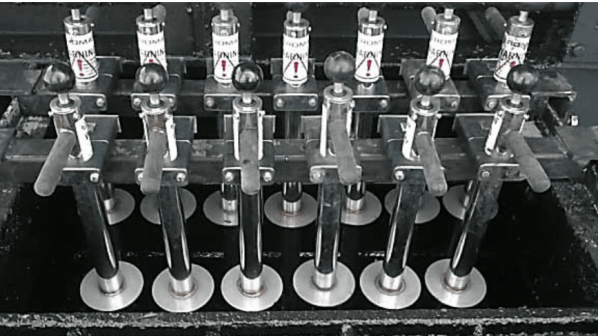

The ROMAR team have completed the latest well on an ongoing UK milling campaign. The client has reported that our SS1000 system is “working extremely well” with 2,998 ft of casing and liner milled at an average ROP of 5 ft/hr with zero non-productive time or lost time incidents