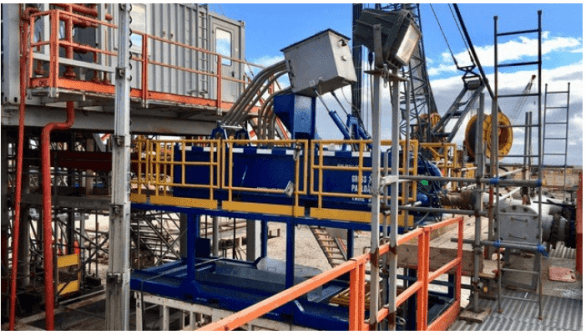

The photo below shows our Ez-Clean ditch magnet system being run on a rig in the Middle East to clear metallic swarf debris from the well with a much greater degree of efficiency and safety than is possible with bar magnets. If we can help improve efficiency and safety