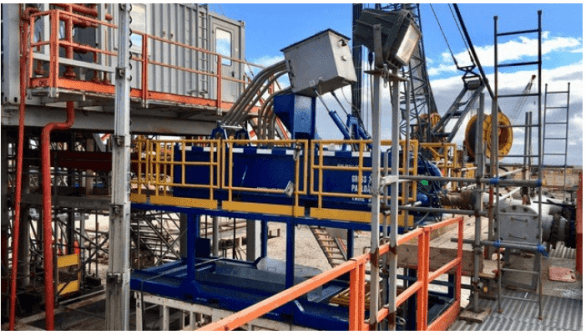

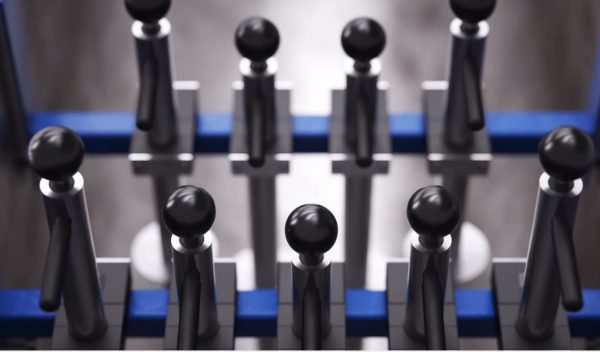

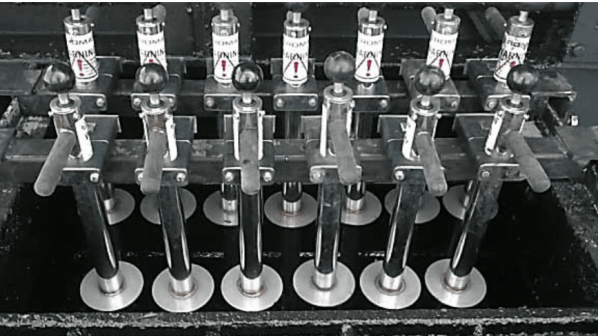

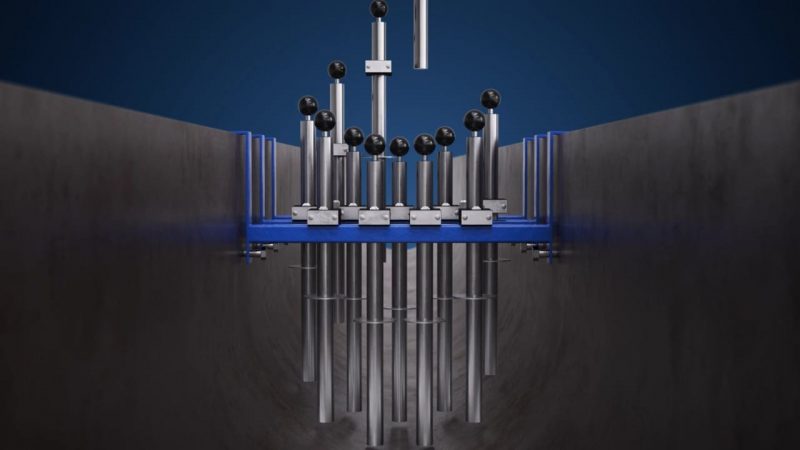

We’re shipping another Ez-Clean ditch magnet system to an operator in the Central North Sea. Each frame covers the full width and depth of the rig header tank for optimum coverage. Most importantly, our Ez-Clean rods can be cleaned without the operator contacting sharp metal shards, a considerable safety