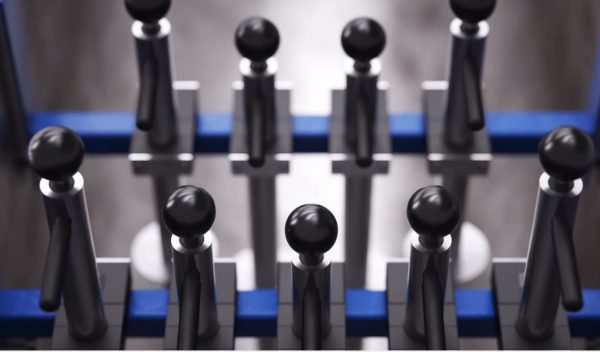

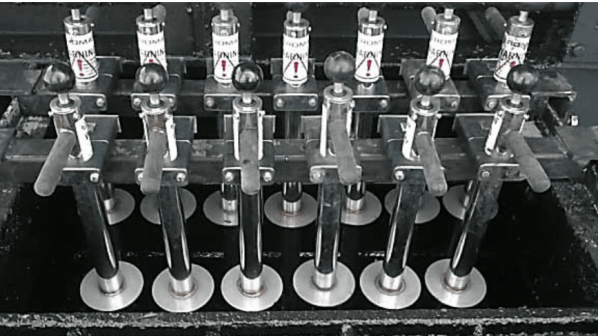

The ROMAR® team have been commended for the high level of service quality attained on a recent SS1000 swarf handling job in the Central North Sea. Our crew received the maximum possible feedback rating from the operator for QHSE Engagement, Proactivity, Cooperation & Communication, Equipment Performance, Personnel Attitude &