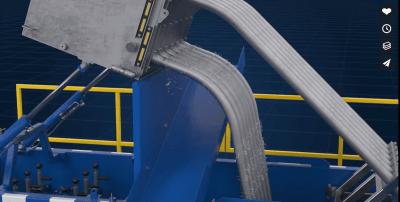

The ROMAR International team has completed another well abandonment operation, this time in East Africa. Our SS1000 system optimized both safety and performance on this land-based campaign. If we can assist optimizing performance on your decommissioning or slot recovery work, then don’t hesitate to get in touch at info@romar-abrado.com