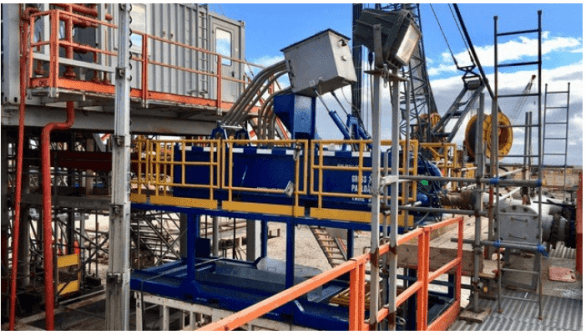

Just before the current Covid-19 shut down, ROMAR International completed a whipstock side-track job for a land rig operator in the Middle East using our EZ-CLEAN MAGNOROD® Ditch Magnet System. The use of the EZ-CLEAN MAGNOROD® Ditch Magnet System for a Whipstock side-track is a great example of how