Romar International and Abrado Wellbore Services Merge to Form ROMAR-Abrado

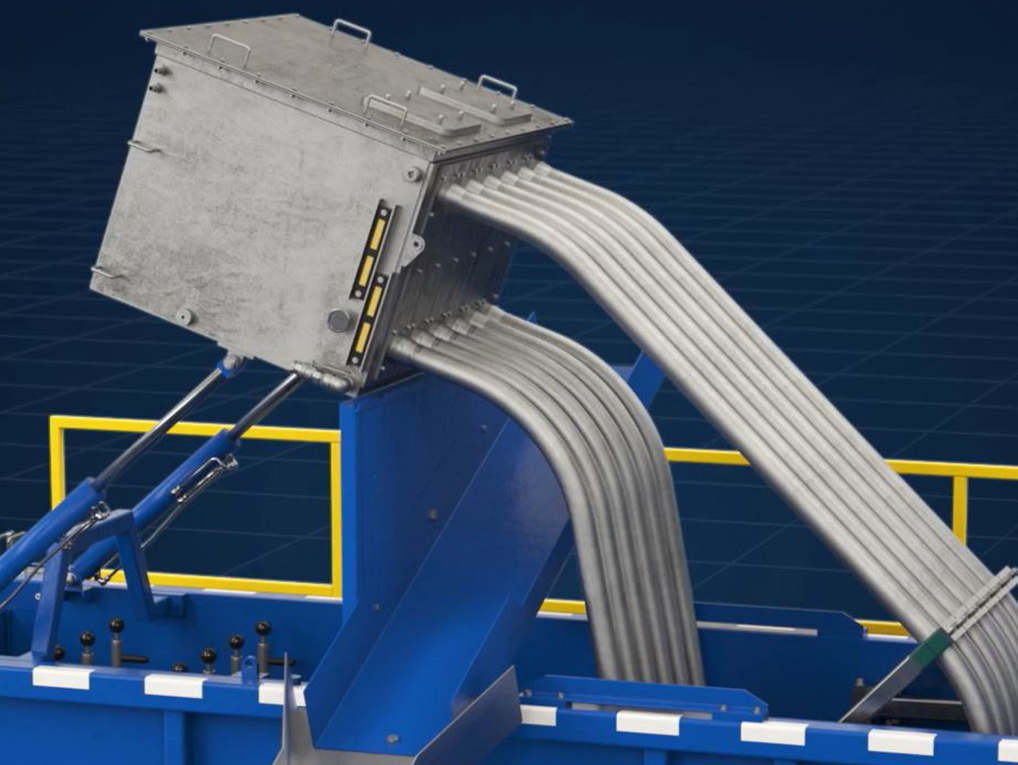

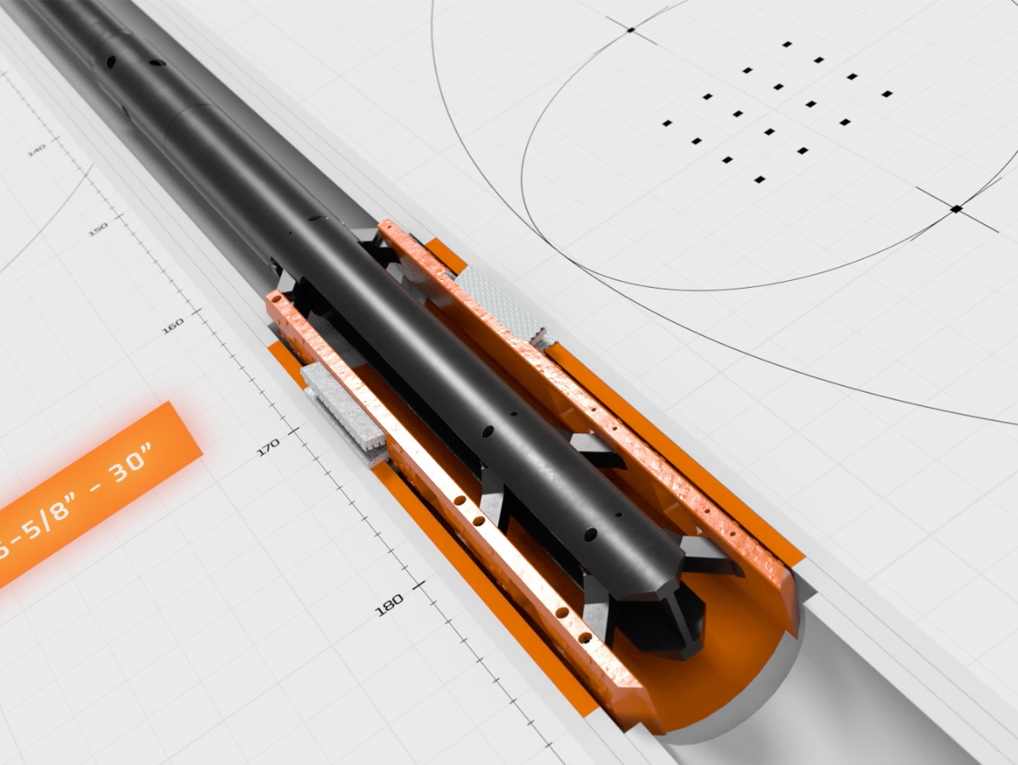

Romar International, experts in magnet separation and Abrado Wellbore Services, industry leaders in precision milling and the facilitation of rock-to-rock barrier placements, are merging their identities to form Romar-Abrado.